As a benchmark in the industry, SOUTHWORTH can not only provide standardized tilters which are widely used for picking parts from packing boxes, operating tables, product stacks and other important places, but also, relying on our strong design team, develop customized tilters with high safety and efficiency to meet individual requirements for manufacturing and assembly process, which may vary largely due to different weight and shape of products, work stations or operation procedures. The case shared today is about the tilter applied by a new energy company for transportation of fragile products.

The unique requirements of this new energy company are mainly lie on the large weight of raw materials and finished products, as well as the increased difficulty in transporting glass and other fragile products. SOUTHWORTH's team developed this tilter specially for this customer based on investigation and analysis of important information, e.g., the material flow of production lines and specific operation process.

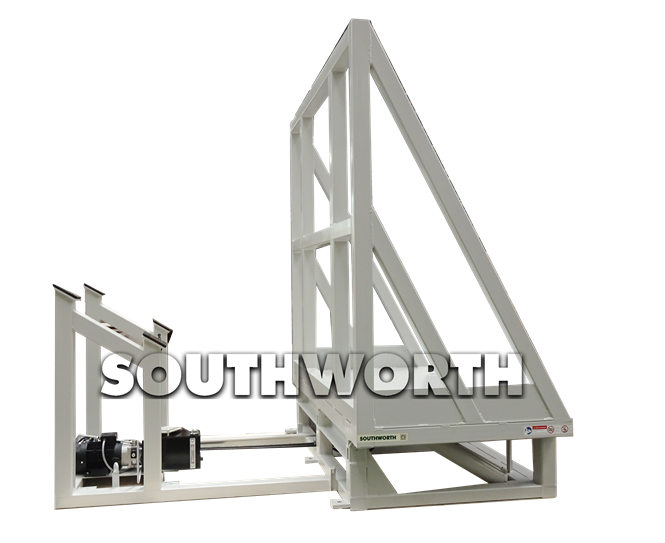

The tilter features a maximum load capacity of 3T and a 2m x 1.2m platform equipped with anti-fall frames on three sides. With a tilting angle of 60°, the loading and unloading height can be easily adjusted according to the production line. Thanks to the high-quality oil cylinders and hydraulic system, precise and gentle tilting operation can be ensured, without violent vibration.

SOUTHWORTH has established an experienced, professional and efficient team that is committed to developing and designing customized lifting, tilting and handling products for various scenarios, and providing customers with professional one-stop solutions covering consulting, planning, design, manufacturing and installation. If you are interested in our products and solutions, please contact us according to the following details, or access more information via our WeChat video account, Douyin official account or our website.

Tilters