SOUTHWORTH lift tables are extensively used in assembling, inspections and spraying of vehicles, engine assembling, brake pad manufacturing, tyre assembling, seat mounting and dismounting and other occasions in the auto industry. This time, our customizable products featuring functions of lift and tilt are chosen by a Germany-invested auto parts factory.

This auto parts factory has a staff of more than 1,000 after the phase-I production base was put into production. Its products are mainly sold on the international market and partially on the market in China. To meet the high quality requirements, the production base purchased the most advanced equipment and technologies in the world. While planning for the logistics equipment for brake discs in the factory, the client chose SOUTHWORTH noted for its high quality and high customizability.

The brake disc workshop is highly automated: the loaded brake discs are sent to the lift and tilt tables at different stations through AVG carts. The brake discs are then lifted and turned to a proper angle by the lift table for easy pick-up by operators without bending down. The proceed brake discs are put back to the lift and tilt table easily by the operators. After that the AVG carts can send the boxes containing the brake discs to the next station.

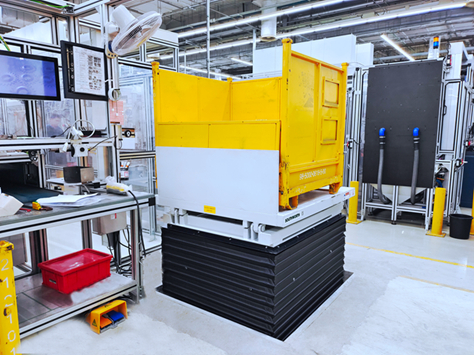

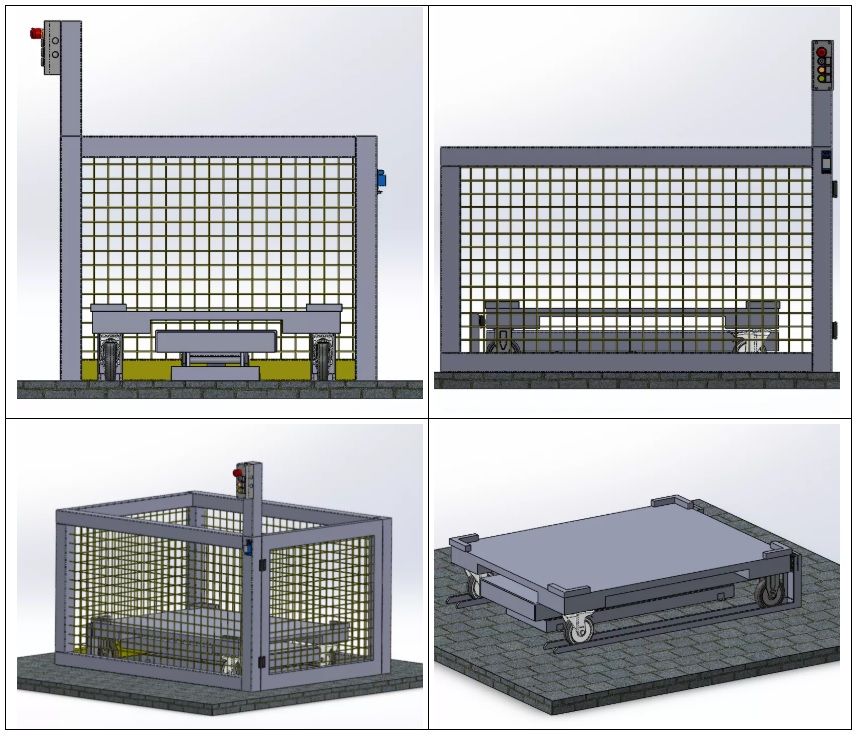

The lift and tilt table has a rated load of 1 ton, surface dimensions of 1.1m x 0.4m, guardrails on three sides and a door on the other side. It is specially designed with a door opening interlock and a table limit and can be started only after the door is closed and the table limit is reached, which ensures maximum safety in operation. Thanks to its built-in power unit, it can be easily installed without a pit.

SOUTHWORTH products are extensively used in the auto industry.