Safety, efficiency, automation, and customization have been the key indicators for material transportation in the auto parts industry all the time. A Guangzhou Auto Parts company, as a customer of SOUTHWORTH, put forward higher requirements for fine management of materials with its rapid increase of orders and expansion of the business scale in recent years, and therefore since 2018, has purchased several customized lifting equipment from SOUTHWORTH through a large Japanese system integrator in order to improve the production efficiency.

The company was facing some problems e.g., large quantity of materials and products, insufficient storage in the factory, low material turnover efficiency, poor docking of cargo trucks for loading and unloading materials. According to the customer’s requirements, SOUTHWORTH's design team worked with system integrator and then developed a complete handling, loading and unloading system specially for the logistics docking process among various equipment in the factory.

Upon arrival of materials in the unloading area, the lifting platform is raised until it is aligned with the rear doors of trucks, and materials are pulled out with the assistance of customized roller beds, and then transported in any of four directions according to the location where materials are to be stored. For delivery of products, goods conveyed from four directions are collected by the lifting platform simultaneously and then transferred into trucks conveniently and quickly for transportation.

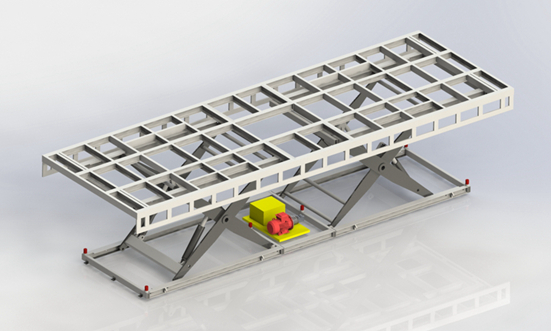

SOUTHWORTH customized dock lift, with parallel dual-scissor structure, are able to realize rapid lifting and lowering operations. Platform bodies are composed of heavy-duty anti-torque rectangular tubes to minimize deformation, and configured with straight-through shafts to improve the stability in the entire stroke range. With a load capacity of 9t and the platform dimensions of 10 m × 3.5 m, these platforms are designed with customized roller beds which not only enable rapid transportation of auto parts, but also allow omnidirectional convey of materials or products driven by the propulsion force in four directions.

According to the feedback for this project, i.e., the third batch of platforms supplied by SOUTHWORTH , the customer’s equipment engineer said, “We fully believe in SOUTHWORTH’s design and manufacturing capabilities for this kind of customized heavy Dock lifts.” 'We have been introduced the lifting platforms designed and manufactured by SOUTHWORTH since 2018, and found that these platforms have been running smoothly and quickly without any quality problems. Due to the expansion and upgrade of our warehouse and production lines, we have placed additional orders immediately to SOUTHWORTH. '