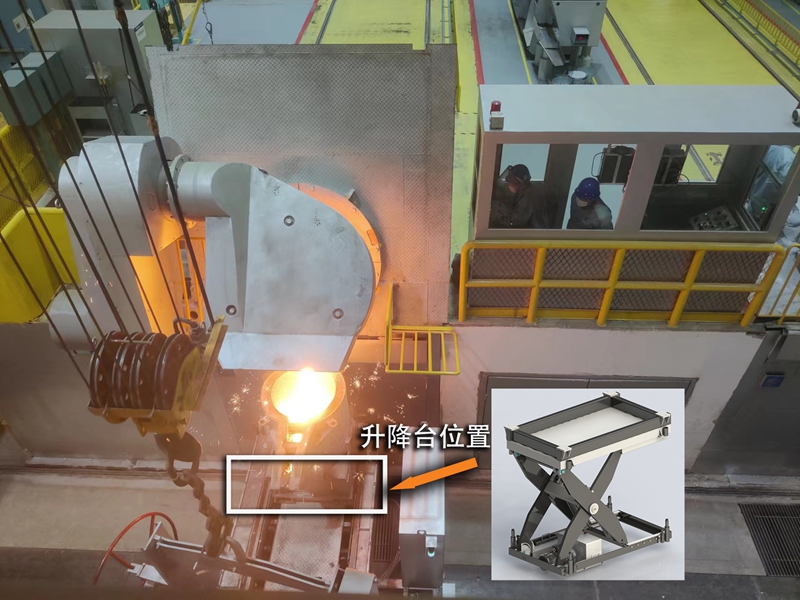

In the casting workshop of a multinational enterprise's mechanical manufacturing center for spare parts, the operating environment is extremely harsh, with high temperatures, limited operating space, and heavy raw materials, all of which pose challenges during operations. This also leads to very high requirements and strong functionality for supporting equipment for metal furnaces.

In the smelting and casting process, automated guided vehicles (AGV) transport molten iron ladles into the metal smelting workshop. Due to limited workshop space, when pouring molten iron from the furnace into the molten iron ladle, issues such as splashing, incomplete pouring, and excessive pouring can occur, leading to splashing of molten iron from the molten iron ladle and damage to surrounding facilities. These issues significantly affect safety and efficiency, plaguing the entire industry.

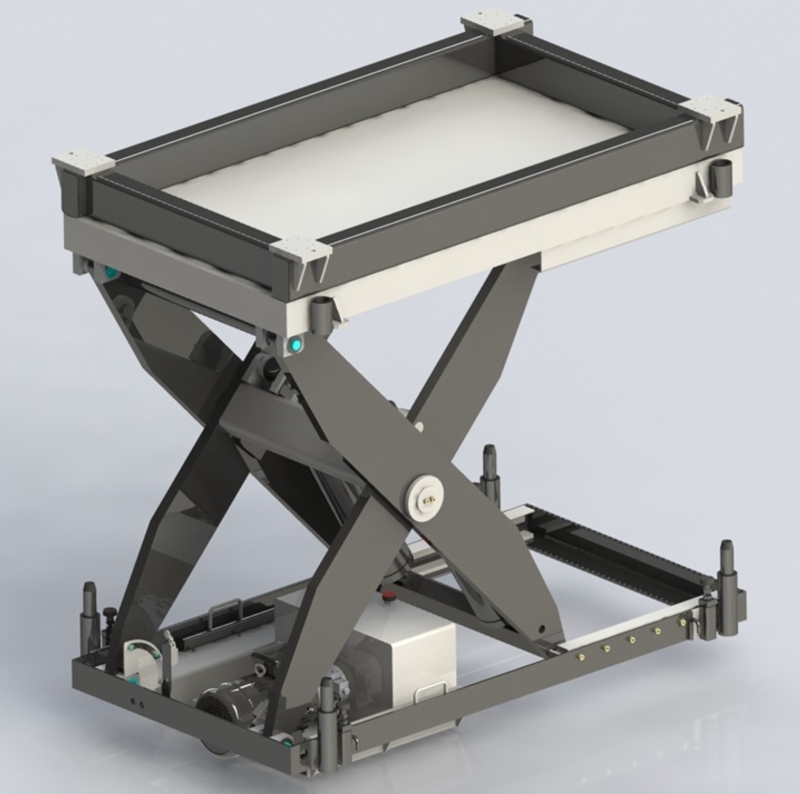

The specially customized lift table by Southworth team is integrated with AGV vehicles. When transporting empty molten iron ladles to the lift table, they are securely fixed onto the platform. As the lift table rises, the furnace pours molten iron into the molten iron ladle. When the molten iron reaches a certain height, the lift table lowers, and the furnace continues pouring. This ensures that molten iron is poured without splashing, maximizing operational safety and efficiency.

Lift table load capacity: 4,000kg

Table size: 1,800mm*1,106mm

Vertical lift height: 1,200mm

Minimum closed height: 460mm

Lifting time: 18s

Southworth has long-term partnerships with numerous clients in the metal smelting and heat treatment industries, boasting extensive design and manufacturing experience, and offering personalized customization services. If you have any needs, please don't hesitate to contact us as soon as possible.