Project Background

Recently, an intelligent storage base of a large new energy manufacturing center with lift tables supplied by Southworth has been successfully put into operation. The three-dimensional warehouse of tens of thousands of square meters realizes the efficient operation by making full use of space based on the logistics storage system and effectively reducing logistics costs.

Problem in AGV interconnection

During the planning and design process, the intelligent warehouse integrator encountered an inevitable problem. When conveying materials to the warehouse shelves, AGVs can only move horizontally and cannot move upward or downward. This makes it impossible to interconnect the AGVs with the fixed height horizontal conveyor rollers.

Southworth Customized Solution

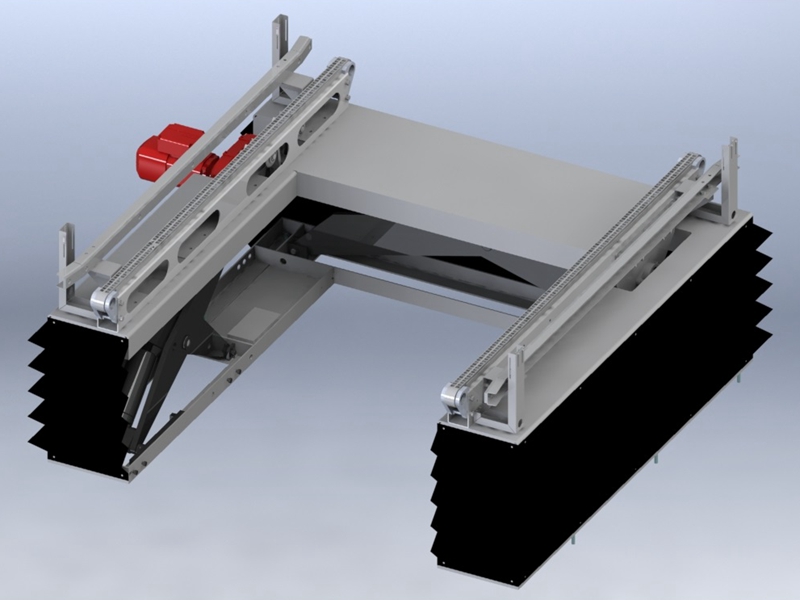

Southworth's pre-sales team surveyed the material handling line and supporting facilities on site and customized a U-shaped lift solution. It consists of three shear forks with three integrated tables. The AGV conveys the materials together with the pallet to the U-shaped internal area of the lift table, and unloads the pallet. That is, it falls to the lift table surface, the AGV retreats, the lift table rises and lifts the pallet and the materials to a suitable height, and then the horizontal roller conveyor carries them to the corresponding position of the three-dimensional shelf.

What is a multi-scissor parallel lift table?

The multi-scissor parallel lift table has been a classic product of Southworth. Under special working conditions, special shaped conditions, or in case of a long table surface, a single scissor lift table cannot meet the demand. Southworth team specially designed multiple scissor units to lift the table surface together to achieve the lifting operation required by the special work station. This type of lift tables requires a simultaneous lift by multiple control units, based on precise calculations and strict technical requirements to achieve a smooth and stable lift.

In recent years, with the rapid development of intelligent logistics featured by the integration of automation, high speed and informatization, Southworth actively conducts the close cooperation with major integrators, and focuses on R&D and design of lifting equipment to provide a wider range of solutions for customers. In addition, Southworth’s equipment is widely used in a variety of industries, including the automotive and parts, wood processing, assembly lines in the manufacturing industry, packaging, and air transportation. Through thorough evaluation and testing, the Southworth team has always been able to find logical and efficient solutions for a wide range of complex applications.