Accessing parts in containers is one of the most significant productivity thieves in any manufacturing or assembly operation. Southworth container tilters improve productivity and safety by positioning baskets so that parts are easily accessible without bending, stretching, or reaching. Southworth offers more models and configurations of container tilters than any other manufacturer.

Fixed tilters for chemical industry

Fixed tilters are ideal for applications requiring non-lifting operation, which can be placed directly on the floor or mounted on a platform to enable a tilt angle of 30˚ or 45˚, for easy access to items without bending, reaching or stretching. The container tilter shown below is specially designed to transport polymer materials to be used in the chemical industry and has been highly recognized by customers.

Lift and Tilt table for Automobile industry

The brake disc workshop is highly automated: the loaded brake discs are sent to the lift and tilt tables at different stations through AVG carts. The brake discs are then lifted and turned to a proper angle by the lift table for easy pick-up by operators without bending down. The proceed brake discs are put back to the lift and tilt table easily by the operators. After that the AVG carts can send the boxes containing the brake discs to the next station.

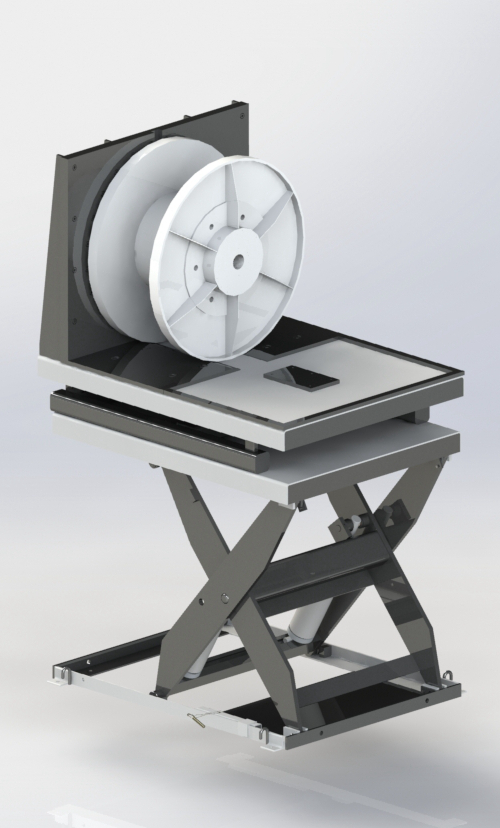

Lift and Tilt table for Metal industry

According to the specific requirements of a company manufacturing metal products, SOUTHWORTH has developed a lift & tilt table integrated with the lifting and tilting mechanisms to allow wire reels (e.g., copper wire reels in this case) to be loaded on the platform. After being transported onto the lift & tilt table, the whole spool of copper wire outsourced can be placed to the desired position for processing through the lifting and tilting operations of the platform. For this application, the equipment with higher load capacity and positioning precision are required.

Lift and Tilt table for Wind energy industry

It is sufficient for the customer to use only the lifting function of the table when installing top-end parts of the wind power generation equipment. For long and soft cover plates, it is required to lower one side of the table to complete a certain installation process first, and then elevate this side of the table to a higher position so that the end of the cover plate to be mounted can be lifted up with the tilting of the other side in order to facilitate the attachment of bolts.After the installation process is completed, the equipment can be quickly transported to the next station by the lift table which is able to ensure convenient and flexible operation due to its mobile design.

SOUTHWORTH tilters are designed to improve productivity and safety , and they have been widely applied in a variety of fields, such as manufacturing industry, power industry, logistics & warehousing industry, chemical industry, energy industry and metal products industry.