As the clean energy industry develops rapidly, its demand for high-purity graphite has risen sharply. The primary problem to be solved by clean energy companies is how to transport large and heavy raw materials to the processing position and lift them to the heat treatment reacting furnaces during smelting, processing, ingot casting and other technological processes.

Customized Transporting Track

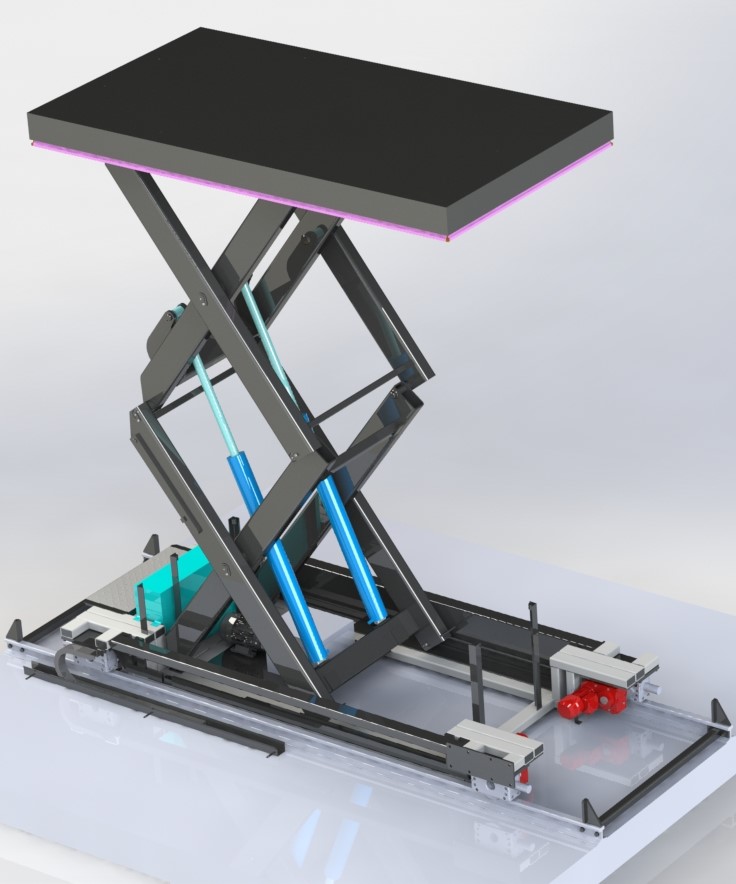

Based on the processing methods of the smelting and processing center, material flow lines and the characteristics of raw materials, SOUTHWORTH team designed a set of track-type mobile lifting system perfect in functions for the materials and processing procedure of the company. It is used to horizontally move raw materials to the reaction place and then automatically lift them to the reacting furnace. With this system, materials can be moved quickly within a limited space while ensuring safety, reducing workers' operation intensity and improving production efficiency.

a

a

Promote the Development of the Clean Energy Industry and Enhance the Productivity

Product Features

SOUTHWORTH track lifting platform consists of two-stage scissors and forks. This high-stroke workbench combination can be lifted and lowered at the same time. Its highest point can meet the height requirements while saving a lot of space.

It can meet the strict requirements of customers for pressure maintaining and the fixed platform will not drop within 2 hours.

The table is 3 meters long and 1.6 meters wide, which can meet the needs of stacking large-volume goods.

The vertical lifting height is 3 meters. When it reaches to the highest point, the raw materials can be transported to the reacting furnaces.

The horizontal moving distance is 5 meters. The horizontal transportation of raw materials and finished products can be realized with specially designed tracks.

The minimum height is 0.7 meters, which is convenient for the handling of raw materials and finished products.