About Forklift Assembly Line

Safety and high efficiency have always been the operation requirements of the assembly line. The orders from our long-term cooperative customer, a large forklift manufacturing center in Jinan, Shandong Province,China, have surged in recent years, indicating an increasingly expanding assembly scale and raised requirements for refinement of production and assembly. However, different types of forklifts will have different heights and irregular shapes because of the specificity of forklifts. This makes SOUTHWORTH's specially customized worker platforms indispensable equipment for the assembly line of the forklift manufacturing center for many years.

SOUTHWORTH Solutions

According to the characteristics of forklift manufacturing center's production line, the flow mode of materials and personnel, as well as the characteristics of assembled products, SOUTHWORTH design team has developed a set of fully-functioning U-shaped lifting equipment for the customer's assembly and docking process. The purpose is to assure workers' safe and enable efficient assembly operations for products with different heights and different assembly requirements, so as to enhance the automatic production level, reduce the operation intensity and improve the production efficiency.

Enhance the level of automation

Improve the production efficiency

Product Features

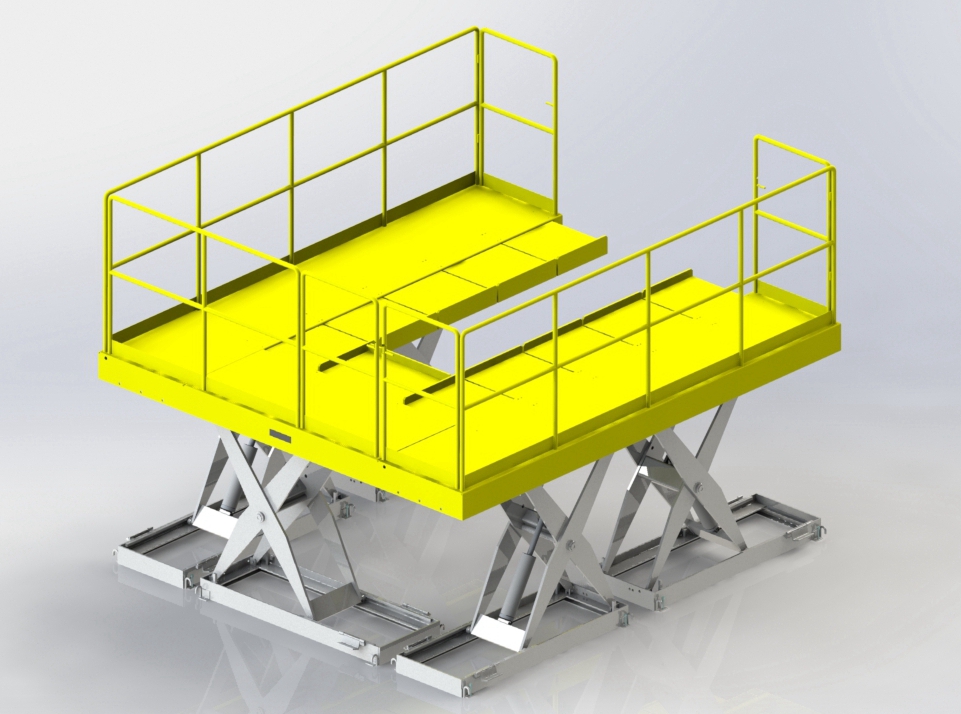

SOUTHWORTH U-shaped worker platform is composed of five scissors forks. Two lift table combinations are on the left and right sides, while the fifth lift table is on the front end for connection. These allow the worker platform combinations to lift synchronously;

The load-bearing capacity of each of the three parts of the worker platform is greater than 1.2 tons;

Telescopic bearing plates are provided on three sides of the U-shaped worker platform, so that workers can stand on the telescopic plates according to their needs when there are special assembly requirements. The bearing capacity of the telescopic plate is more than 500 kg;

Guardrails are set on three sides of the worker platform, and a sliding door is provided at the front opening, which will be locked when the lift table rises to prevent safety accidents caused by personnel stepping on the air;

The extended pedals should be fully retracted to the platform before lifting

Customer Feedback

This is a project that requires additional purchased products for the new manufacturing center. 'From the recent use of lift tables designed and manufactured by SOUTHWORTH, we found that it has been running smoothly and quickly, meeting the requirements of ergonomics and convenient for workers' operation,' according to the feedback from the user's equipment engineers, who said that they asked SOUTHWORTH to manufacture the lift table as soon as their new manufacturing center was established, and thought the lift table would be a necessary for each new production base of theirs.

ABOUT SOUTHWORTH

SOUTHWORTH has an experienced, professional and efficient team that dedicates to customizing and designing lift tables for various scenarios, integrating consultation, planning, design and installation, and continuously providing professional solutions for customers.