The goods are generally placed on the ground in traditional loading and unloading which are inefficient, inconvenient and time-consuming. Or, a platform is built at a height close to that of the carriage. However, it cannot address the problem of height difference and clearance faced by trucks with different heights, making the forklift unable to access transportation vehicles for direct loading and unloading.

The loading Dock lift is special auxiliary equipment for cargo loading and unloading used in conjunction with the forklift. The forklift can directly drive from the ground or the platform into the interior of the carriage via the platform for batch loading and unloading operations.

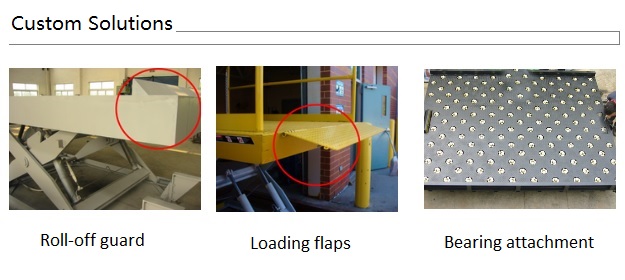

Southworth has designed and manufactured the customized lifting platform for loading and unloading based on such scenarios. With low costs, short cycle and easy installation, it can replace the traditional concrete platform and can also be used in conjunction with the existing platform. Specially customized solutions can be provided based on different industries and companies, their product characteristics and transportation conditions as well as the characteristics of site facilities and the flow process.

As to the double-scissor structure, an extra-long working table is lifted jointly by the lifting system composed of two scissor arms to achieve the required length and load capacity. The Dock lift is a star product of Southworth. The lifting process has been accurately calculated and controlled by the professional design team. All scissor units are lifted synchronously to ensure safe and efficient conveying. The table is equipped with a roll-off guard which rises automatically after the forklift enters the carriage and slides down to place the forklift down.