Industrial ergonomic equipment should always make sure to bring the product a worker is trying to handle or move to a neutral ergonomic position. The Southworth lift table makes sure each box, tote or basket is always at the level of the worker’s belt line, lifting from the bottom up. Schmalz equipment comes from the top down, bringing the box, tote or basket to zero gravity at the belt level.

'While the worker is always being pushed to work faster, most material handling equipment moves slower than the peak speed of a worker,' Schmitz said. 'As such, the warehouse manager or plant manager is stuck between two worlds—they want to do the right thing for the worker and cut down workers’ compensation claims, but they are also pressured to maintain a certain amount of throughput productivity.'

As such, Schmalz aims to come up with a solution in which the worker can move at a slower, more sustainable rate over a full shift and still meet the throughput target. To accomplish this, the worker might have to pick up twice the amount of product normally moved to maintain the quota.

'But sometimes that just isn’t physically possible,' Schmitz said. 'That’s when we recommend to the warehouse or plant manager that they consider full-scale robotic automation. Handling product that weighs even just 20 pounds and moving it approximately once per minute in a single pick adds up to having to move approximately 10,000 pounds in a total of 500 picks across an entire eight-hour shift. Most workers will not enjoy that type of work for very long.'

Some industries are being environmentally conscious and are using large reusable shipping containers. However, the rigid shipping crates have very high fixed sidewalls that make it hard for workers to reach into the crates to pull out product.

'In most cases workers are filling or emptying these containers manually, and that’s where we see a lot of injuries due to the worker having to reach over and down to lower or lift product in or out,' he said. 'Industry needs to consider ergonomics for its workers beyond environmental considerations when thinking about its operational processes.'

Workers’ compensation claims of overexertion typically relate to pulling, pushing, lifting, carrying, holding and reaching, said Amy Blueter, vice president of operations at MHI member Kinetic Technologies LLC in Wickliffe, OH.

'When items are in the correct position or in the proper place for an employee, that optimizes what a worker can do and it is often more productive for the company.'

—Amy Blueter, Kinetic Technologies LLC

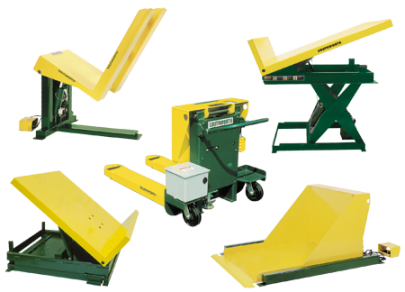

'Positioning materials at a proper ergonomic level is so important to reduce repetitive motion and overexertion,' Blueter said. 'So tilting materials to reduce those motions is a big win!'

A side benefit of tilting and proper positioning of materials is increased productivity.

'When items are in the correct position or in the proper place for an employee, that optimizes what a worker can do and it is often more productive for the company,' she said.

There are many varieties of equipment. Some are movable, which eliminates the need for forklifts in the facility because workers can tow the containers to where they need to be.

'This takes steps out of the process and makes the worker more productive. They can also tow more than one load at a time, which is quite a productivity boost, as well as an added safety benefit,' Blueter said.

Mechanical tilting equipment can pull down to a preset degree, while fixed equipment is always set to some degree and doesn’t move. Some equipment is mechanical, pneumatic or hydraulic, with ranges of tilt from 15 degrees to 70 degrees.

'I don’t think people realize how much safer and more productive workers are going to be when they can work in the proper position,' she said. 'After they implement the towable tilting equipment, they tell us they not only have reduced workers’ compensation claims, but they’ve also reported a productivity increase.'

Kinetic Technologies also offers flexible solutions that can accommodate different heights and arm lengths, because they not only tilt, but they also raise and lower. As such, they can accommodate both a 5-foot-2-inch female and a 6-foot-5-inch male in the 'ergonomic power zone.'

'We collaborate with customers to design the right way for workers to handle objects, so they are not reaching all of the time and hurting themselves,' Blueter said.