In-line with SAPAC (Southworth- Asia Pacific) 5 Years’ Stratplan (Strategic Plan) to double our regions’ sales revenue through delivering “Cost Competitive & World Class Quality Products”, the new supply chain team was established officially on August 8th 2018.

Prior to this, the sourcing function in China was primarily tactical and transactional. Much of the focus were geared towards sourcing & expediting of purchased parts to meet shipment deadlines. Supplier development was near absent and as such purchased parts quality was a major issue.

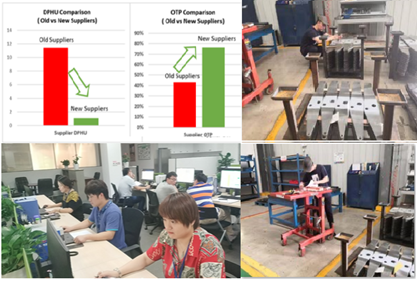

Average defects per hundred Units (DPHU) were about 12 DPHU and these caused frequent production line shutdowns, poor on-time delivery performance (OTP) Customer Complaints & Field Warranties.

Also, there was no linkage with Design Engineering to support MTO & ETO type design projects resulting in extended delays. Our sales team’s ability to meet customer quote lead-time , book an order and deliver on were a major challenge and this resulted in numerous lost sales orders.

Based in Shanghai & led By Nora Zhang, a seasoned practitioner with more than 20 years’ experience in supply chain management, the small supply chain function was re-organized into :-

a) Advanced Strategic Sourcing & Supplier Development

(To better support local sales & engineering plus Corporate SIGI Sourcing projects)

b) Factory Tactical Purchasing & Supplier Quality Management

(To strengthen support Wuxi & Ningbo operations)

Advanced Strategic Sourcing & Supplier Development

To achieve Supply Chain Excellence, the 101’s of Sourcing & Supplier Development capabilities were emplaced into Southworth Advanced Sourcing Function as a default priority.

Some key aspects of the basic fundamentals emplaced are:

Supplier development assessments & approvals were managed with internal cross function teams’ representation. Joint field visits are performed for mission-critical components.

As our nature of business are mostly low volume-high mix (LVHM) lift tables, the team focused only on Tier 2 & below suppliers as they are more cost competitive and agile in supporting our requirements. Tier 1 Suppliers are excluded as they mostly serve large MNC (Multi-national corporations) and costly. To secure the best pricing, the new sourcing process requires a minimum of three quotations from pre-qualified suppliers. Post shortlisting, tough negotiations are initiated to try and secure the most cost competitive price parts for our business.

As part of our company’s factory consolidation plans, the advanced sourcing team focused much of our efforts in establishing a brand new supply chain near to Wuxi Factory. It was a “humongous” task as the project included both “re-sourcing” of more than 1,000 parts from previously purchased parts from Shanghai Old Factory Supply Chain and “Out-Sourcing” of previously in-house fabricated parts at our old factory.

Major difficulties encountered were drawings inaccuracies and incorrect BOM structure and vague quality requirements. Advanced Quality Engineering efforts were thus needed to breach the gap to clearly define quality requirements and train/develop suppliers to meet our expectations beyond a piece of drawing.

Purchased Parts Approval Process (PPAP) were also introduced and fully implemented as this was previously non-existent. Actual prototype sample submission and qualification surfaces potential issues if any and help ensure consistent parts quality post launch.

With the team’s dedication, hard work and strong collaboration (Sourcing- Engrg-Operations-IS), we were able to complete the new supply chain set-up and enable Wuxi Factory to go live on January 2nd 2019.

After a couple of months of start-up , we are pleased to report that the new supply chain is a major success as validated by improved quality where average defects per hundred units have reduced from the former 11.5 to 1.1, supply chain on-time delivery improved from 43% to 76% and last but not least we are at least cost-neutral ( less “outsourced” paint which was unplanned) from a total cost of acquisition perspective.

In the area of linkage with design engineering, similar success is also registered. We have a dedicated buyer partnering engineering to pre-source new parts needed to support potential projects and orders. This has enabled us to do better cost estimates and quotations to customers. Proactive collaborative efforts have enabled us to secure Shanghai Dianba Power Packs, SAFETECH Dock Leveler, Baoji Gen 2 Lift Tables etc projects.

As part of our supply chain management deployment model, we have a very small lean team of 2 buyers & 1 SQE (Supplier Quality Engineer to drive continuous quality improvement) deployed at the factory level to ensure close range support and effective communications.

The factory’s tactical purchasing team’s role is to proactively establish Syteline parameter setting and PO management, running MRP, releasing and tracking PO, monitoring material delivery, coordinating delivery changes, supporting warehouse on inventory management, building up safety stock etc.

In summary, our goal is delivering supply chain excellence for our company so as to achieve profitable growth. We are not there as yet and much work needs to be continued.

The SAPAC supply chain team will continue its journey of continuous improvement and strive forSupply Chain Management Excellence. The basics of policies, procedures, systems and reviews arenow in place and It will be the foundation for future success.

As an example, our next phase of Supply Chain Development will include initiatives like PFMEA, GR&R, APQP etc. We will also develop right-sizing initiatives to consolidate supply base through partnering engineering and sales to achieve parts standardization ( e.g. cylinders & ultra-low volume high mix parts). We will also stretch the supply chain to deliver cost reduction through lean initiatives.

Just like the book name from Professor Martin Christopher said, we will keep “Driving Value Through the Supply Chain”, and deliver more momentum to support Southworth business growth.

In Closing, on behalf of S-APAC Sourcing Function, we would like to take the opportunity to thank our company’s executive leadership and China team for the strong support and success. Together, we have an exciting future for S-APAC in the Asia Pacific region.